system description

Design

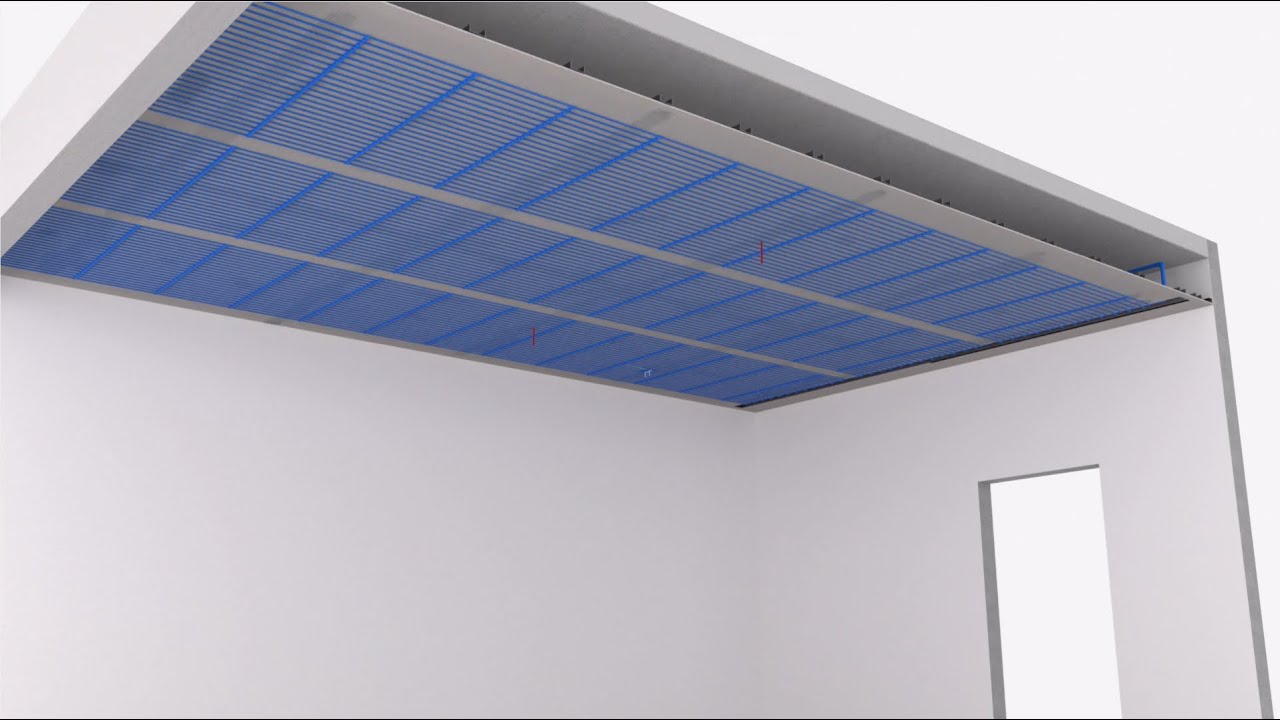

The capillary tube mats are plastered underneath a suspended gypsum board ceiling. On the visible side, a closed, jointless plaster ceiling is created for the dissipation or supply of sensitive heat loads. The water circulates noiselessly in the capillary tube mats and regulates the room temperature largely by radiation, partly by convection.

Capillary tube mat

The Clina capillary tube OPTIMAT SB 20.00 mat is recommended for this design.

Length & Width

The capillary tube mats are custom-made in length and width for each project. On the construction site the mat distributor pipes are connected to each other by heating element socket welding. This is a secure, non-detachable connection.

Hydraulic connection

Mat distributor pipes and supply lines are accommodated in the void of the suspended ceiling. The capillary tube mats, welded together to a hydraulic circuit, are connected to the supply and return lines.

Of course, the ceiling void can also be used for further installations.

Mounting

The capillary tube mats run through a slot in the gypsum board to the room side and are attached there with stainless steel clips or galvanized staples.

Lamps & Ventilation

Larger openings must be considered in the planning phase. Up to approx. 100 mm, openings can also be realised during the construction phase by simply pulling the capillary tubes apart.

Plaster

All commercially available plasters such as gypsum, lime, cement or acoustic plaster are suitable. For example, they are applied using the spraying method up to a plaster layer thickness of 15 mm.

Regulation

The system can be regulated room-by-room.

Fields of application

Suitable for all types of buildings, such as office buildings, residential buildings, hotels, etc., whether new construction or renovation.

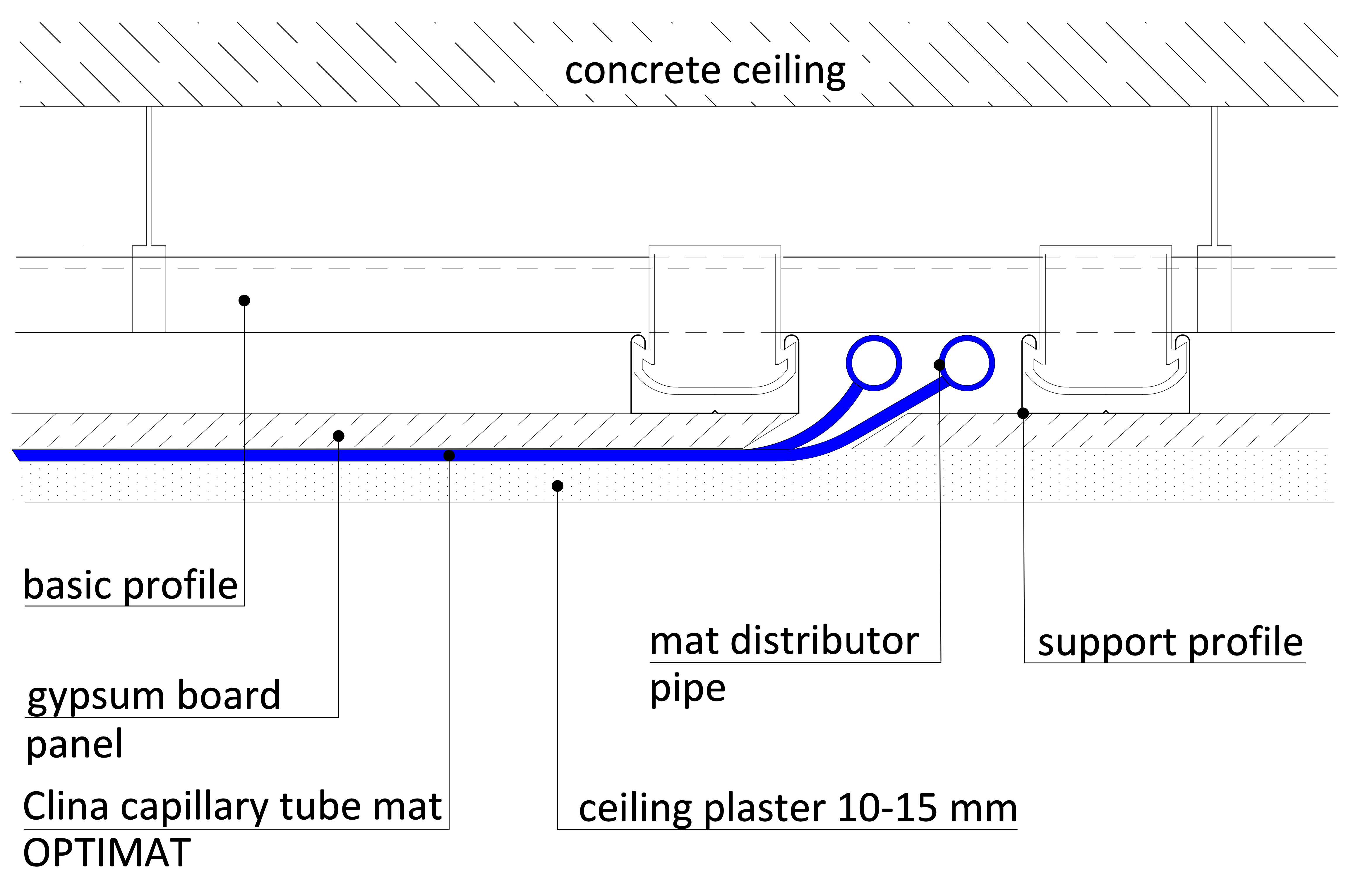

structure

View of a ceiling section: plaster on gypsum board

The capillary tube mats are plastered underneath a suspended gypsum board ceiling.

Mat distributor pipes and supply lines are accommodated in the void of the suspended ceiling.

The capillary tube mats run through a slot in the gypsum board panel to the room side and are attached there with stainless steel clips or galvanised staples.

Plaster, for example, is applied using the spraying method up to a layer thickness of 15 mm.

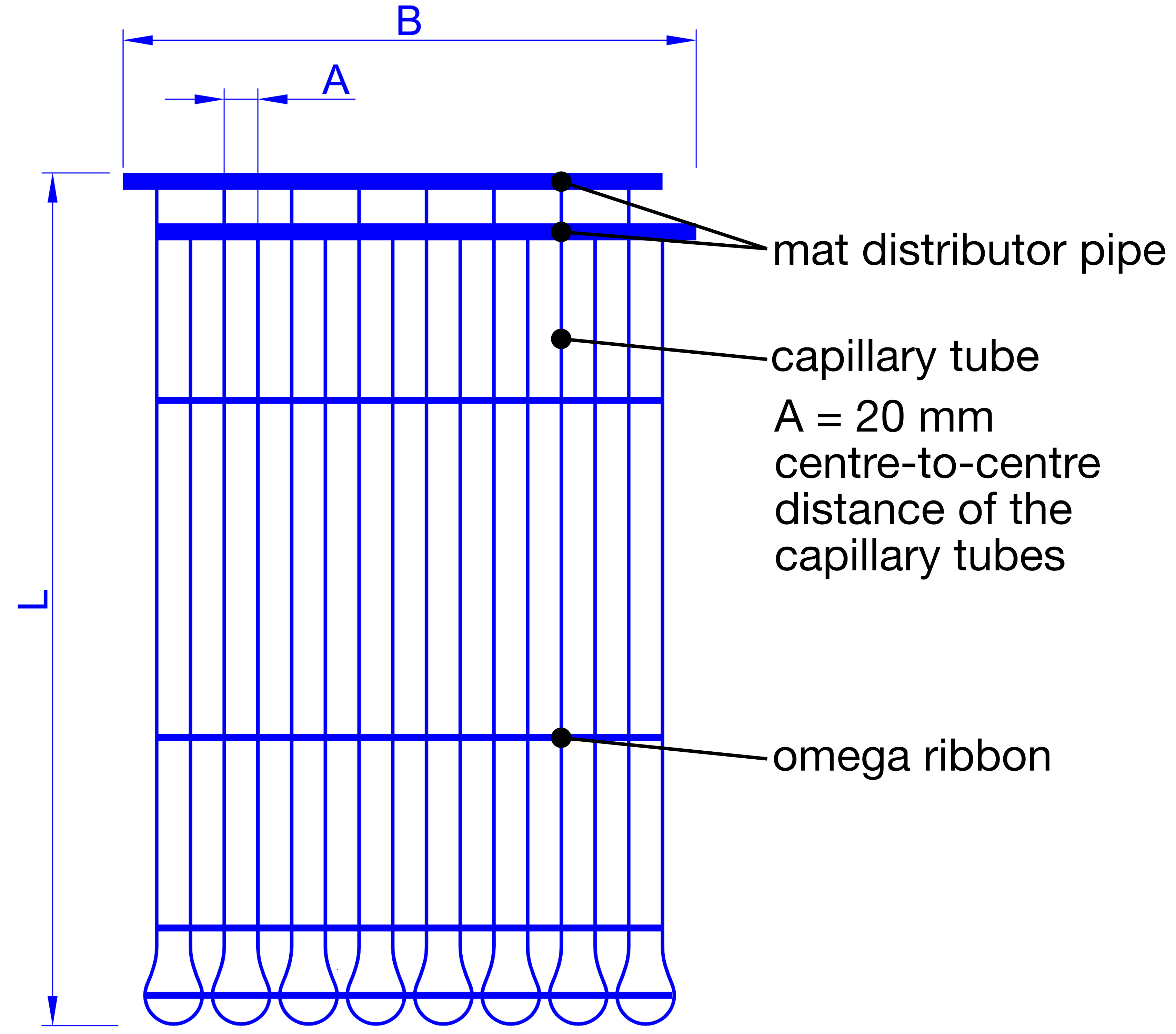

recommended capillary tube mat

The OPTIMAT SB 20.00 consists of 2 round mat distributor pipes (20 x 2,0 mm) and capillary tubes

(4,3 x 0,8 mm).

The constant distance between the capillary tubes (centre-to-centre distance) is 20 mm and is guaranteed by the omega ribbons.

Special features

- high mechanical resilience

- low pressure loss

- good venting

OPTIMAT SB 20

advantages

Cooling and heating with one system

In most buildings, the heat requirement to be covered is so low due to the well-insulated building envelope that capillary tube mats invisibly integrated into the ceiling not only provide excellent cooling in the summer, but can also be used to heat very comfortably and energy-efficient in the cold season.

High performance and dynamics

Due to the capillary tubes completely enclosed by the plaster, a large-area heat conduction is achieved. The near-surface layer with a low plaster coverage ensures a fast response. This design allows a maximum degree of activation of the ceiling.

Good price/performance ratio

The use of large-sized capillary tube mats reduces the installation effort. The usual plaster layer thickness is not affected by the capillary tube mat. There are no additional costs for material.

Very low installation height

A complete embedding of the capillary tubes is achieved with a plaster layer thickness of 10-15 mm. The mat distributor pipes and supply lines are placed in the ceiling void.

Very flexible

This design can be adapted to all spatial conditions, e.g. also to spaces with vaults and archs.

Individual room control

The temperature can be regulated room-by-room.

Better than component activation

The plaster ceiling convinces with significantly higher dynamics, performance and surface quality.

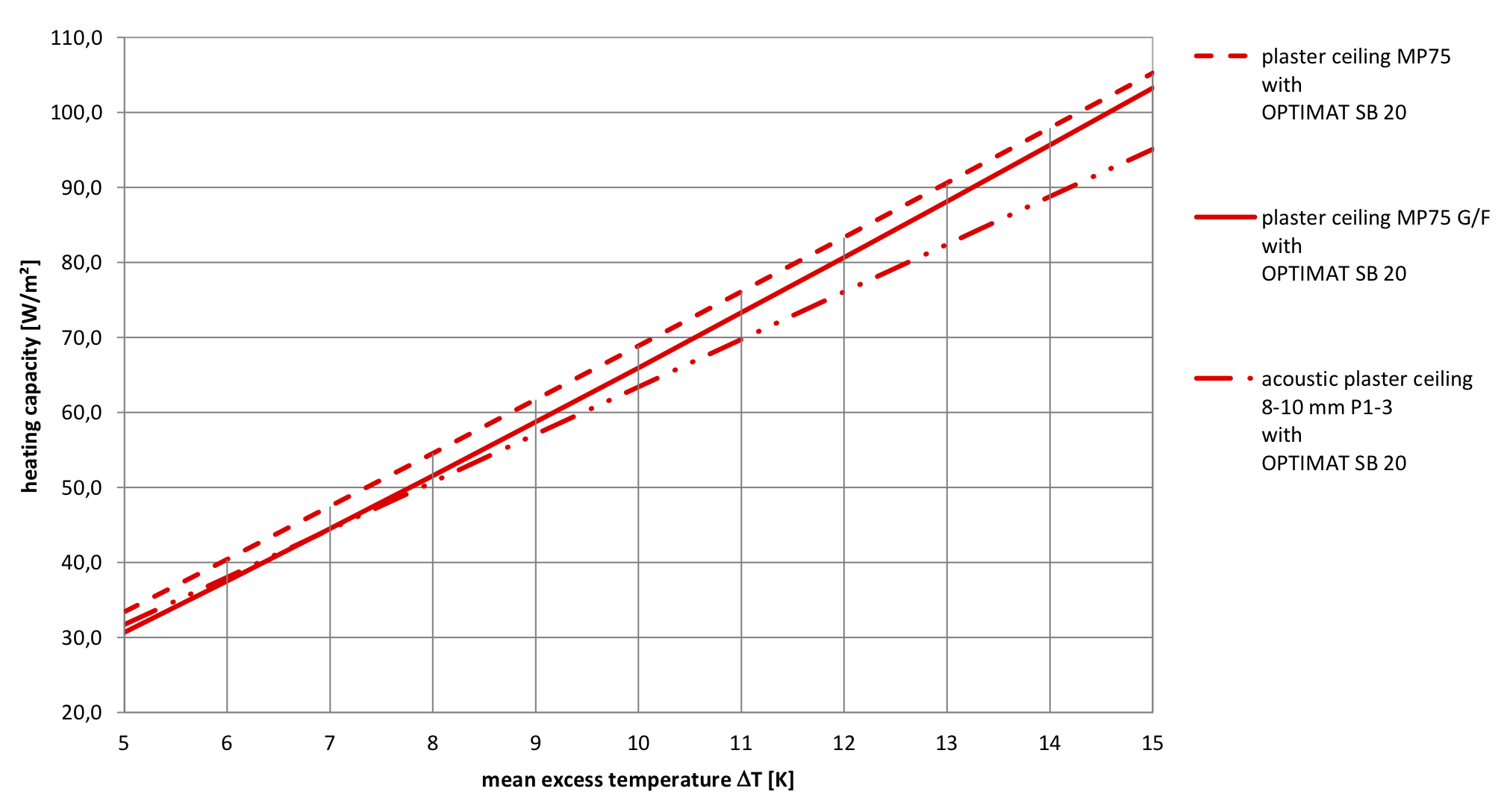

values

|

HEATING CAPACITY according to DIN EN 14037/5 |

COOLING CAPACITY according to DIN EN 14240 |

ACOUSTICS |

|

105,3 W/m² (MP 75) |

90,6 W/m² (MP 75) ΔT = 10 K, active mat surface |

weighted sound apsorption coefficient according to plaster manufacturer‘s specifications |

|

INSTALLATION HIGHT: |

SYSTEM WEIGHT: |

PRESSURE STAGE: PN 10 |

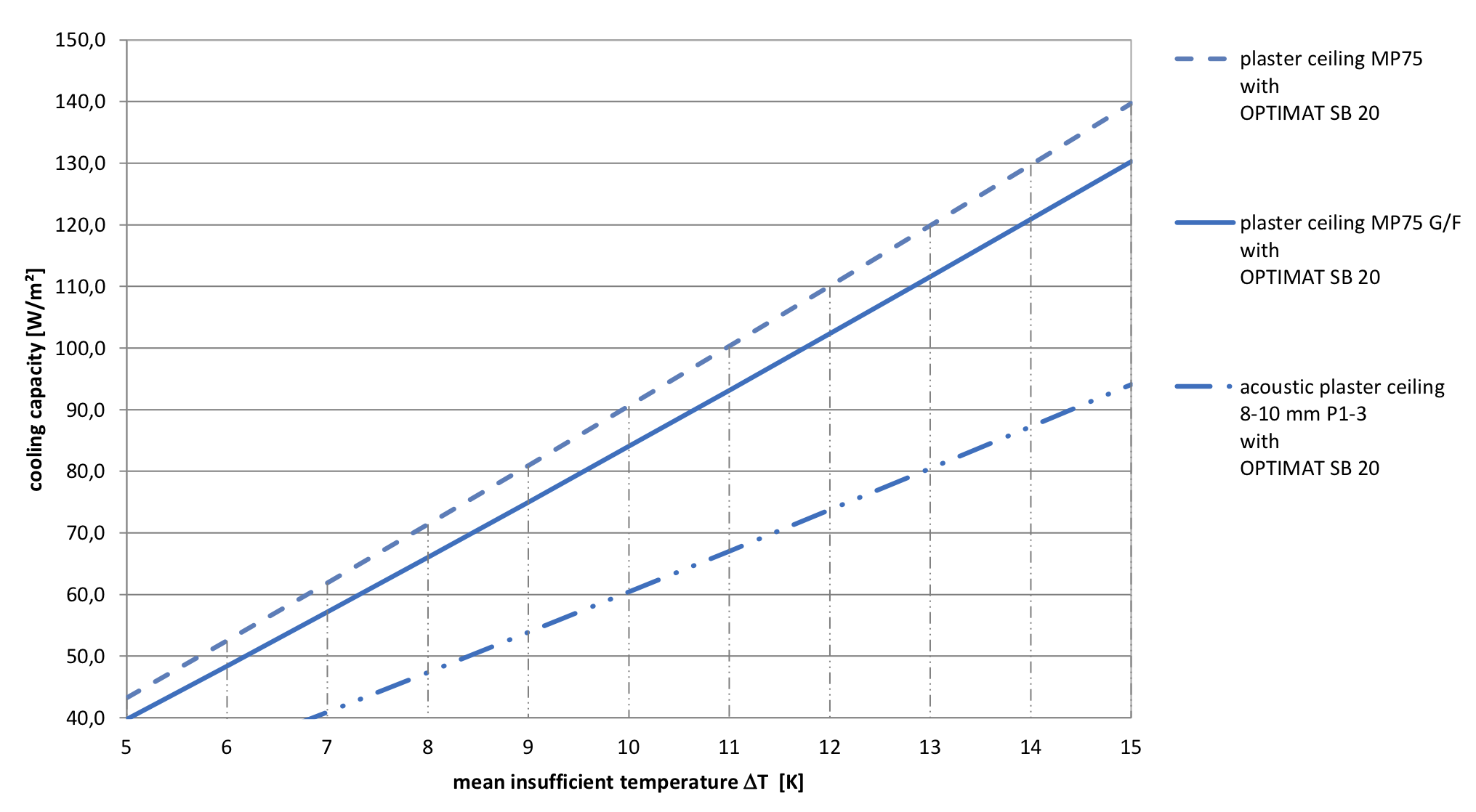

performance diagrams

SPECIFIC COOLING CAPACITY ACC. TO DIN 4715 / DIN EN 14240

SPECIFIC HEATING CAPACITY ACC. TO DIN 4715 / DIN EN 14240 / 14037-5 (DRAFT)