description

The system solutions offered by Clina use PP capillary tube mats and PP pipes which are oxygen-diffusion-open. Since the presence of oxygen leads to corrosion, it is essential to design the secondary circuit with corrosion-resistant materials. This also applies to the circulation pump. We recommend the use of plastics, stainless steel, bronze, red bronze or copper. Of course, the offered assembly does meet these requirements.

Until the saturation limit is reached, oxygen, not to be confused with air, enters the system. Due to the oxygen diffusion through the PP, a system separation is implemented using a stainless steel plate heat exchanger.

This ensures a complete and thus a material separation of the primary and secondary circuit. In order to reliably protect the Clina system from dirt and corrosion, we recommend using our separation systems.

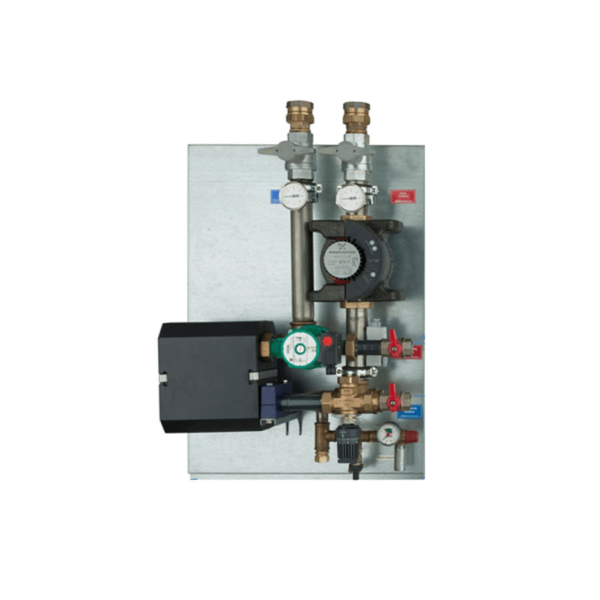

Clina offers separation systems with performances of 3,5 to approx. 50 KW. These separation systems mainly consist of the following components:

- controlled bronze or stainless steel circulating pump

- stainless steel - plate heat exchanger

- constant flow temperature control

- safety valve

- over-temperature-protection device

- membrane safety valve

- membrane expansion tank with connecting-kit

The entire station is built on a stable, galvanized mounting frame and prior to delivery it is subjected to a leak test with 10 bar water pressure.